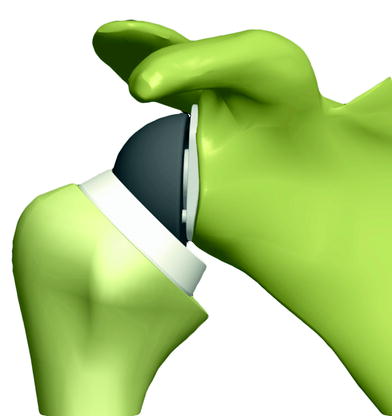

Fig. 35.1

Factors influencing inferior contact: a Reference position. b Superior translation of the baseplate. c Superior inclination of the baseplate

These various modifications have repercussions on the position of the vertical and lateral center of rotation but also on the stresses applied to the glenoid baseplate. The superior positioning of the baseplate (Fig. 35.1b) and its superior inclination (Fig. 35.1c) clearly appear to be predictive factors for the appearance of conflict [10, 11].

Conversely, if all the biomechanical parameters are combined in favor of reduced inferior conflict, theoretically we obtain a more distal baseplate with inferior inclination and a lateralized glenoid of large diameter [8–11]. However, what can be modeled on a biomechanical plane does not necessarily correlate with what is possible and desirable in vivo.

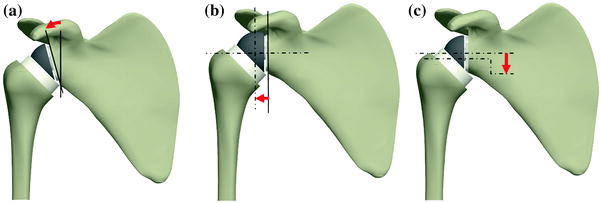

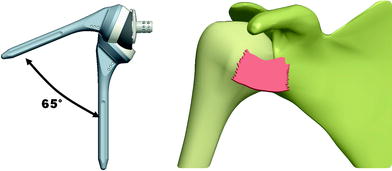

Even though the inferior inclination of the glenoid baseplate (Fig. 35.2a) appears to be a good mechanical solution in terms of distribution of stress and limitation of conflict, it requires significant rasping of the inferior section of the glenoid surface. Excessive rasping can compromise the hold of the implant and cause bone loss. The inclination of the baseplate through inferior rasping must therefore be avoided in our opinion.

Fig. 35.2

a Inferior inclination of the baseplate b Lateralization of the glenoid. c Inferior eccentric positioning of the glenoid

The choice of a lateralized glenoid involves lateralization of the center of rotation (Fig. 35.2b) which results in excessive stresses on the glenoid baseplate and reduction of the lever arm of the deltoid. This goes against the initial design of the implant where the medialization of the center of rotation produces reduced stresses on the baseplate while increasing the deltoid strength.

Therefore, we did not want to move toward this route.

Some authors [12] have suggested the addition of an osseous slice behind the baseplate (Bio-RSA). This idea is an elegant solution to overcome the problem of medial stresses linked to lateralization since the bone consolidates and eventually becomes part of the patient. The lateralization that this creates is probably beneficial to the action of external rotators but reduces the lever arm of the deltoid, which is not without mechanical repercussions on the force required for abduction. According to the authors, it appears that with this technique, notch occurrence is slightly less than 20 % over two years [12].

The distal positioning of the baseplate recommended by some authors seems to be poorly reproducible and the origin of poor positioning of the inferior screw.

An eccentric glenoid seems to combine the advantages of simple positioning of the baseplate with distal positioning of the glenoid which is recommended to avoid notching.

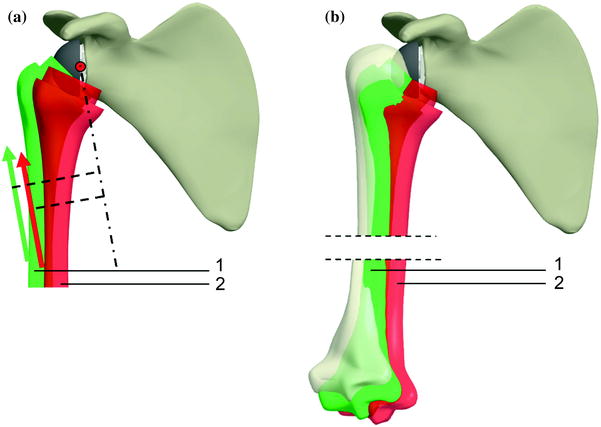

Cut Angle for the Prosthetic Implant

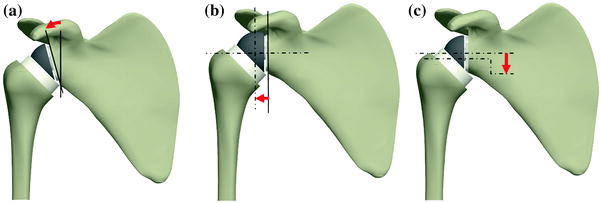

The adduction deficit depends on 5 main factors, only 4 of which involve the glenoid positioning. The cut angle of the humerus is a major mechanical factor (Fig. 35.3). A recent mechanical study clearly revealed the harmful effects of a valgus cut and the beneficial effects of a varus cut [11].

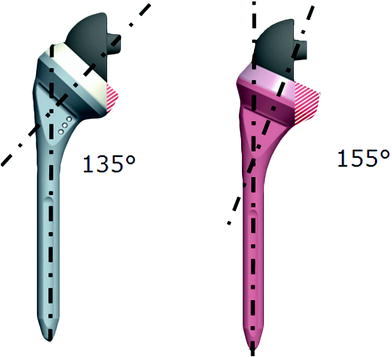

Fig. 35.3

Comparison of notch risk (represented in stripe), for a design at 135° (left) and a design at 155° (right)

The chosen cut angle of 155° was justified during the design of the first reverse implants through maximum implant stability research.

The horizontalization of the cut theoretically better opposes the subluxating forces directed vertically during the initiation of abduction. However, this design is not without any other repercussions. This leads to medialization of the humerus which reduces the desired lever arm effect in particular. This medialization does not just have a detrimental effect on the deltoid abduction strength but also decreases the efficiency of the external rotators. It is also partly responsible for an adduction deficit, which is potentially responsible for the appearance of notches. Finally, in combination with the lowered humerus, it is partly responsible for the unsightly “shoulder pad” appearance due to the medialization of the humerus.

Other Factors Potentially Influencing Scapular Notching Occurrence

The existence of a macrophage reaction linked to the polyethylene debris is one of the potential causes of loosening of all implants using this type of friction torque. The stress characteristics of the reverse implants can potentially lead to a significant increase of the wear of this material in comparison with a standard prosthesis. A recent interesting study by Farron and Terrier [13] concluded from a numerical model that there is a fivefold increase in the volume of debris in reverse implant cases in comparison with a standard implant.

This therefore remains a significant concerning factor for the long-term survival of the implants. The use of highly cross-linked polyethylene is a partial solution to this problem, but the use of another friction torque is probably an essential line of research to be considered for the future.

Combined Solutions for Designing This New Implant: Design Features of the Scultra Ii Reverse Implant

Through analysis of these different factors which potentially influence the occurrence of a notch, we have attempted to combine the various solutions which appear valid into a single implant. We therefore chose to associate a humeral implant with a 135° cut and a hemispheric eccentric glenoid.

A 135° Neck Angle Prosthesis

During abduction, the horizontalization of the humerus leads to gradual horizontalization of the resulting forces toward the center of rotation. It is therefore mainly at the initiation of the movement that the force vector resulting from the deltoid action is close to vertical and potentially subluxating. The horizontalization of the cut is justified to oppose this effect. However, this theoretical situation cannot be transposed in vivo since complete adduction is impossible with a 155° design. We therefore noted that the start of abduction takes place obligatorily with an angle of 15° to 20° relative to vertical and therefore to the glenoid surface. Verticalization of the cut by 20° therefore produces an identical mechanical situation (the resulting abduction forces only change slightly with the slight abduction of the humerus to 20°) and therefore only has a small impact on the implant stability.

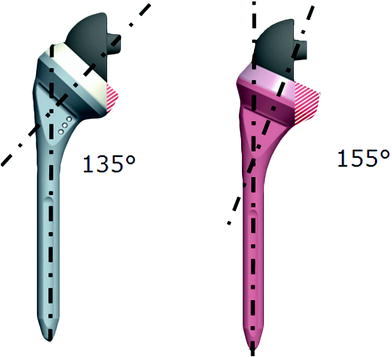

The mechanical simulations performed also revealed a theoretical limitation of abduction linked to verticalization of the cut (Fig. 35.4) of around twenty degrees which varies depending on the type of glenoid implant used [11].

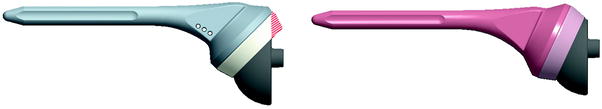

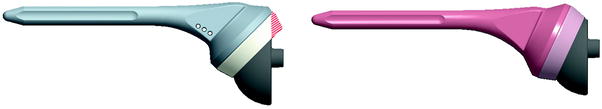

Fig. 35.4

Comparison between the SCULTRA II design (left) and an implant with a cut angle of 155° (right)

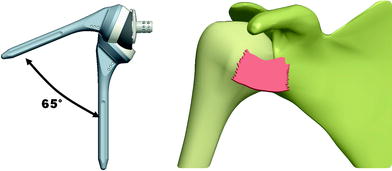

Again, this limitation is theoretical since in vivo pure abduction is theoretically limited to less than 70° by the joint capsule (Fig. 35.5); this was confirmed by kinematic studies on reverse implants [14].

Fig. 35.5

Abduction limitation due to the joint capsule

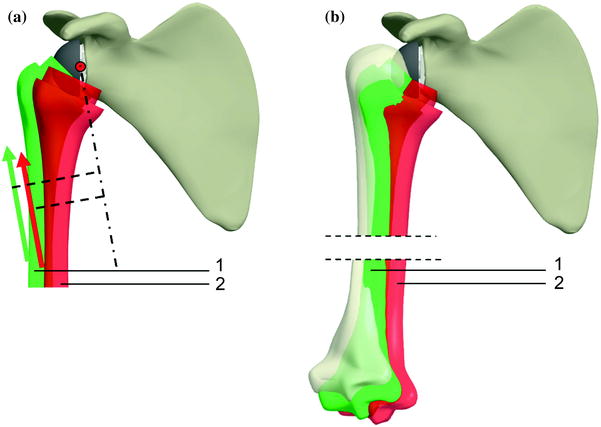

Performing a cut at 135° leads to lateralization of the humerus by around 5 mm which results in a beneficial increase of the lever arm of the deltoid (Fig. 35.6a) and an improved aesthetic appearance (the position of the humerus is more anatomical; Fig. 35.6b). It also results in reduced lowering of the humerus by 5 mm; however, this is partly offset by the lowering of the center of rotation (2 mm) linked to the eccentricity of the glenoid in the case of the SCULTRA II prosthesis. Deltoid stretching, advisable to increase its strength of contraction [15], therefore remains consistent.

Fig. 35.6

Influence of the cut angle on lever arm of the deltoid, (a) and the aesthetic appearance (b) 1 cut angle of 135°; 2 cut angle of 155°

An Eccentric Glenoid

We chose a solution in which the baseplate is positioned where the bone stock is better and where exposure enables accurate surgery (Figs. 35.2c and 35.7).