Chapter 17 Wheelchairs and Seating Systems

There is a wide range of choices in wheelchairs. One can choose a wheelchair that is manual, geared, fully powered, power assisted, or standing. There is also an abundance of seating and postural support hardware that can be used to correct or accommodate a wide range of orthopedic deformities and conditions. These include contoured cushions and backrests, tilt-in-space, recline, and custom-molded seating systems. The goals for a wheelchair or seating system are listed in Box 17-1.

Minimize the Risk of Secondary Injuries

Tips and falls account for more than 70% of wheelchair-related accidents.43 It is imperative that individuals be provided with mobility devices that comply with internationally recognized wheelchair standards and can be safely operated (as determined by a skilled therapist or assistive technology professional). Seat belts, wheel locks, and a properly adjusted wheelchair can prevent serious wheelchair-related injuries. Pressure ulcers are also a significant risk for those who use wheelchairs. Advanced cushion designs and seat functions can provide adequate pressure relief for persons who cannot independently off-load the buttocks. Shoulder pathology and nerve compression injuries at the wrist are common among wheelchair users.41 Using proper wheelchair propulsion biomechanics and an optimal wheelchair setup can help delay the onset of overuse injuries.

Ensure Comfort

Along with mobility, comfort has been reported as the most important attribute or function of a wheelchair.16 Research has shown that most wheelchair users experience regular discomfort. Many either ignore it or seek relief by getting out of the wheelchair, using pain medications, or doing weight shifting (either manually or with tilt and recline).16 A wheelchair that allows for “fine-tuning” of the adjustments provides greater options for achieving comfort, as well as meeting the individual’s postural and pressure needs.

Manual Wheelchairs

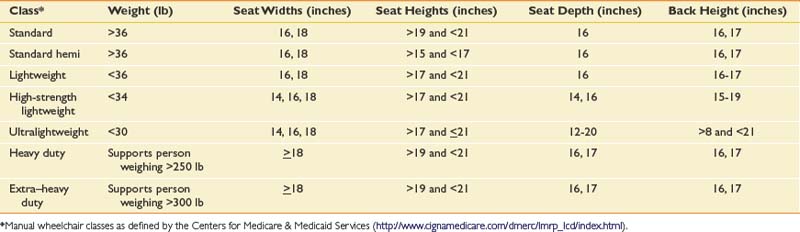

Persons with good upper body function and stamina might well be able to use a manual wheelchair for mobility. Manual wheelchairs for daily use are often categorized by their design features and costs. Table 17-1 provides an overview of each adult wheelchair category as defined by the Centers for Medicare & Medicaid Services (CMS), which is the leading third-party payer for wheelchairs. The categories are outdated and are being revised to reflect the actual composition of manual wheelchairs on the market.

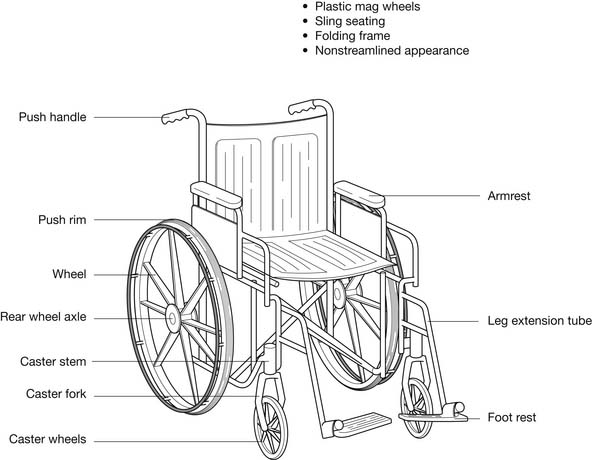

The standard wheelchair (Figure 17-1) is designed for short-term, hospital or institutional use and should not be recommended for the patient to use as a personal wheelchair. As noted in Table 17-1, these can be rather heavy with limited sizes available. Figure 17-1 also illustrates the basic components of a wheelchair. The standard wheelchair folds for easy storage and transportability. A “hemi” wheelchair is essentially a standard wheelchair with a lower seat-to-floor height for persons of shorter stature or who use one or both feet for propulsion. A lightweight wheelchair is slightly lighter in weight but with limited sizes. The first three models have few adjustable parts (some models have no adjustable parts) and generally have sling-type upholstery. Sling upholstery has no capacity to provide pressure relief, and the hammock effect that occurs from wear causes uncomfortable and unstable inward rotation of the hips. However, many users have been sitting in a sling seating system for years and have become accustomed to the hammock effect for comfort. Making the switch to a seating system that supports their posture better can be both frustrating and uncomfortable for these users.

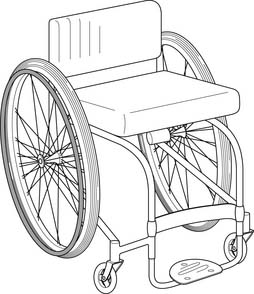

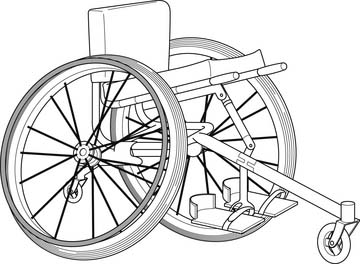

The high-strength lightweight and ultralight wheelchairs are designed for long-term use by individuals who spend more than a couple of hours each day in a wheelchair. They have adjustable features, especially the ultralights. There are many advantages to using ultralight wheelchairs over the other wheelchair types. These are highlighted in the following sections that discuss selecting the appropriate seat dimensions, setting up the wheelchair, propulsion mechanics, and transportability. An ultralight wheelchair is depicted in Figure 17-2.

The last two classes of manual wheelchairs listed in Table 17-1 pertain to persons who weigh more than 250 lb. These wheelchairs are heavier than the wheelchairs in the other classes, to support more body weight. These categories are also outdated because of the increasing number of persons with disabilities who are overweight or obese and need wheelchairs. This trend has resulted in an expanded class of “extra–heavy-duty” wheelchairs, referred to as bariatric wheelchairs, which are built to support individuals who weigh between 300 and 1000 lb.

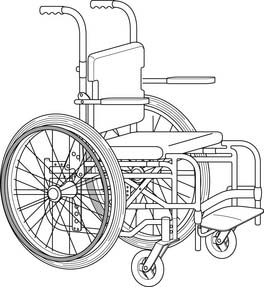

Pediatric manual wheelchairs are similar to the adult wheelchairs but are smaller (seat width or depth <14 inches). Many of these wheelchairs have adjustable frames or kits for accommodating the growth of the child (Figure 17-3). If the child is unable to self-propel the chair, a powered mobility device might provide independent mobility.37 Strollers equipped with a wide range of seating options (Figure 17-4) can also be used to transport children with orthopedic deformities.

Sports wheelchairs are designed specifically for participating in such athletic endeavors as racing, rugby, tennis, and basketball. These wheelchairs are made of lightweight materials, and usually have very aggressive axle positions and camber. Some of the sport wheelchairs have only one wheel in the front, which allows quick turns and enhanced maneuverability (Figure 17-5). Wheelchairs equipped with arm crank mechanisms (called hand cycles) for exercise are available from many manufacturers. Arm crank exercise can help improve cardiovascular fitness, with research showing that arm cranking is more efficient and less of a physical strain than conventional wheelchair propulsion.33

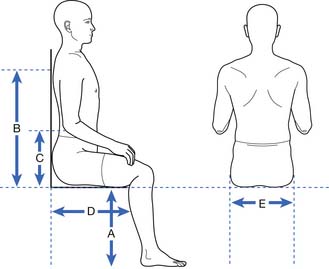

Basic Wheelchair Dimensions

Figure 17-6 shows the measurements that should be taken of the patient’s body for determining wheelchair dimensions. These dimensions are required not only for determining the correct manual (or power) wheelchair size, but also for determining seating system sizes (e.g., cushion, back supports, leg rest lengths).

Seat Height

The seat should be just high enough to accommodate leg length while leaving enough space under the foot rests (about 2 inches or so) to clear obstacles.3 Persons with longer legs often need angled or elevating leg rests that extend the legs slightly outward instead of straight down (knee angle of 90 degrees). This is needed to allow them to get their knees underneath tables. It is more difficult to do if the patient has tight hamstrings. The height of the seat should be adjusted so that the person has enough knee clearance to fit under tables, counters, and sinks at home, at work, at school, and in the community (the Americans with Disabilities Act mandates at least 27-inch-high knee clearance under tables and surfaces). Seat height is also an important consideration for persons who drive while seated in the wheelchair and need to be able to access the steering wheel or hand controls.

Seat Depth

The depth of the seat provides support for the thighs. A seat that is too shallow causes higher sitting pressures because less of the seat is in contact with the thighs. A seat that is too deep can cause excess pressure behind the knees and calves. There can also be a tendency for the pelvis to slide into a posterior tilt so that the back can be adequately supported by the backrest. A 1- to 2-inch gap between the popliteal area and front edge of the cushion is recommended, but might need to be more if the person propels with the feet.3

Back Height

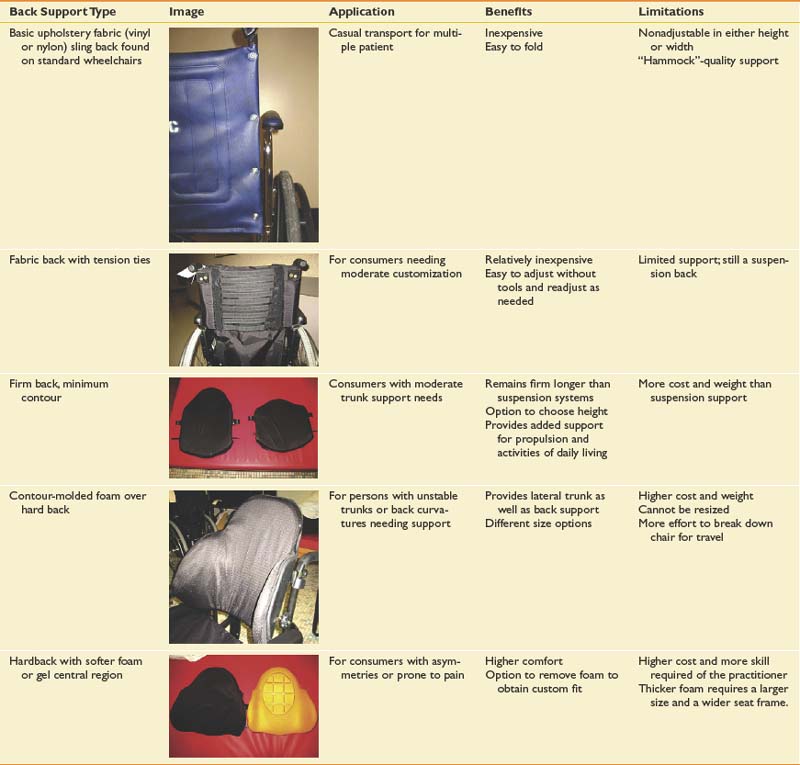

The height of the back is determined by the amount of postural support the person needs. The backrest should be low enough to provide adequate support, but still allow the upper limbs access to as much of the pushrims as possible. Many practitioners use the inferior angle of the scapula as a basis for determining backrest height. The backrest height should be below the inferior angle so that it does not impede arm movements. There are various kinds of back supports (Table 17-2), and some have a tapered area that allows for greater freedom of scapular movement. Only the high-strength lightweight and ultralight wheelchairs permit the attachment of different kinds of back supports.

Manual Wheelchair Setup

Ultralight wheelchairs provide the highest degree of adjustability. This makes it possible to optimize the fit of the wheelchair to the user, which is likely to have a positive impact on propulsion mechanics. In addition to the basic adjustments that can be made on most other wheelchairs (e.g., footrests, armrests), ultralight wheelchair adjustments also allow for adjusting the seat and back angle, rear wheel camber, and rear axle position.

Rear Wheel Camber

Camber is the angle of rear wheel tilt. Zero degrees of camber implies that the rear wheels line up vertically and with the side of the wheelchair. Angling the rear wheels so the top is tilted inward and the bottom outward (see Figure 17-5) results in increased camber and distance between the rear wheels. Most wheelchairs generally have up to 8 degrees of camber. Although more camber is usually possible, it can impede the ability to enter and exit doors and openings. Box 17-2 lists the advantages and disadvantages of camber.

Horizontal Axle Position

Moving the axle forward moves the seat back relative to the rear wheels. This results in a shift of the user’s weight to over or slightly behind the rear axles.9 A more forward axle position requires less muscle effort because rolling resistance is lowered when more weight is distributed over the larger rear wheels than the smaller front casters.31 This position also facilitates “popping a wheelie,” negotiating obstacles, and ascending or descending curbs. In contrast, moving the axle forward can make the wheelchair more “tippy” and difficult to push up a ramp because of the tendency to tip backward. For this reason, wheelchairs are usually delivered with the axle in the most rearward position possible. This position usually needs to be changed, based on input from the patient and the practitioner. An antitipper (Figure 17-7) can help prevent rearward falls; but might also make it more difficult to negotiate a curb and pop a wheelie. Because of the effects on stability, the axle should be moved forward incrementally, provided the wheelchair user feels stable. Adding weight to the chair can also affect stability.27 This is why packages or backpacks ideally should be located underneath the seat of the chair.

Vertical Axle Position

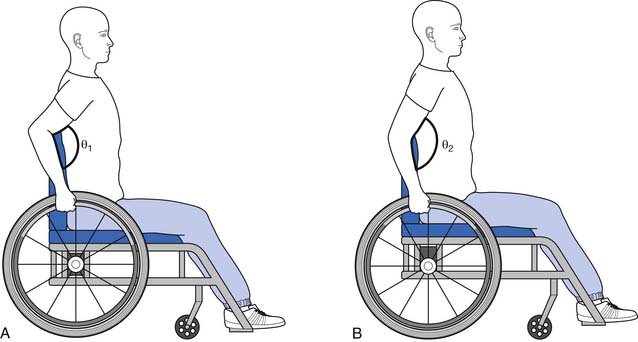

Raising the axle has the effect of lowering the seat, while lowering the axle raises the seat. A lower seat position can improve propulsion biomechanics by increasing hand contact with the pushrim,5,44 lowering stroke frequency,5 and increasing mechanical efficiency.44 Lowering the seat height also increases the stability of the wheelchair. If the seat height is too low, however, the patient has to push with the arm abducted. This can increase the risk of shoulder impingement, another upper limb injury common among manual wheelchair users. The ideal seat height is the point at which the angle between the upper arm and forearm is between 100 and 120 degrees when the hand is resting on the top and center of the pushrim (Figure 17-8, A).5,44 An alternative method that can be used to approximate the same position and angle is to have the individual rest with their arms hanging at the side. The fingertips should be at the same level as the axle of the wheel. If the seat height is too high, less of the pushrim can be accessed and more strokes are needed to go the desired speed (Figure 17-8, B).

Wheelchair Propulsion

Wheelchair Weight

The weight of the wheelchair is an important consideration, especially when prescribing manual wheelchairs. Less propulsive force is needed to push a lighter wheelchair. Ultralight wheelchairs have frames and components made with materials having high strength-to-weight ratios, so less material is needed. One study directly compared ultralight and standard wheelchairs, and found that ultralight wheelchair users pushed at faster speeds, traveled further distances, and used less energy.4 The reduction of force is even more important on inclines where gravitational forces add to the rolling resistance. A light wheelchair is also easier to load into and out of a vehicle.

Quality of the Wheelchair and Setup

Ultralight wheelchairs have better components and are less likely to become misaligned with use, which helps minimize rolling resistance. Keeping the chair in good alignment might require other adjustments, such as to the brakes or caster alignment or height. Axle tubes on rigid ultralight frames can eliminate many of these problems. As discussed previously, a wheelchair that fits the user and is optimized for propulsion by adjusting the axle position makes it easier to push the wheelchair. Lowering stroke frequency and forces through a combination of propulsion training, wheelchair setup, and proper choice of wheelchair can protect the median nerve from injury.7 Instrumented wheels used in prior research15,36 are now available commercially for clinicians to use to objectively evaluate the quality of wheelchair setup and propulsion techniques.

Propulsion Technique

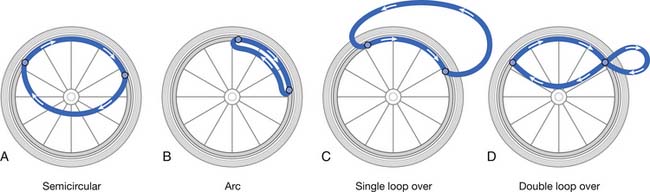

The propulsion techniques of manual wheelchair users have been examined in detail.6,38,40,46 Propulsive strokes are generally described in two phases: when the hand is in contact with the pushrim applying forces (push phase), and when the hand is off the rim and preparing for the next stroke (recovery phase). Four distinct propulsion patterns have been identified, which are defined by the path the hand takes during the recovery phase: arc, semicircular, single-looping over, and double-looping over (Figure 17-9). The single-looping over form of propulsion, which consists of having the hand above the pushrim during recovery, is the most prevalent pattern in individuals with paraplegia.6 However, the semicircular pattern, in which the user’s hand drops below the pushrim during recovery, has better biomechanics (see Figure 17-9, A). The semicircular pattern has been associated with lower stroke frequency and greater time spent in the push phase relative to the recovery phase.6 The semicircular pattern is preferred because the hand follows an elliptical pattern, with no abrupt changes in direction and no extra hand movements. By applying forces to the pushrim in smooth, long strokes, the same amount of energy is imparted to the rim without high peak forces or a high rate of force loading. For example, a long stroke (see Figure 17-9, A), as opposed to a short stroke (see Figure 17-9, B), is likely to minimize the number of strokes needed to push at a desired speed.

Manual Wheelchair Transportability

There are basically two types of manual wheelchair frames: folding and rigid. Folding frames allow the wheelchair to collapse for storage (see Figure 17-1). Rigid frames are mainly available for ultralight wheelchairs (see Figure 17-2) and for wheelchairs with special positioning aids (e.g., tilt or custom seating systems). Rigid frames tend to be more durable than folding because there are fewer moving parts. Fewer moving parts also mean that rigid frame wheelchairs tend to be lighter. The backrests on rigid frames are designed to fold down for improved compactness. A “quick-release” axle allows for easy removal of the wheels on rigid frames and certain folding frames. This option is not available on standard and some lightweight wheelchair models.

Manual Wheelchair Components and Accessories

Refer also to the discussion on seating and positioning.

Wheels and Tires

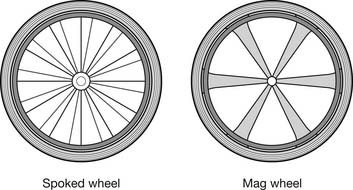

There are several factors to consider when choosing the most suitable wheel and tire configuration for a wheelchair including type of indoor or outdoor terrain, activity level, maintenance, weight, and cost. Many standard and lightweight wheelchairs come equipped with either mag-style or spoked wheels (Figure 17-10). Mag wheels are made from composite plastics or metal (initially they were made from magnesium, hence the term mag). They are usually heavier than spoked wheels but are more durable and require less maintenance. Newer types of mag wheels are composed of high-strength lightweight materials and can even be lighter than spoked wheels, but are more costly. Spoked wheels have a tendency to get out of alignment (wheel wobbles when spun), requiring a trip to a bicycle shop or a wheelchair dealer for the wheels to be trued.

Grade Aids

Grade aids are devices that attach to the frame and are used for persons who have difficulty with slopes and have a tendency to roll backward down hills. These devices only prevent the wheelchair from rolling backward, and forward motion is unimpeded.

Pushrims

Pushrims are available in different sizes, shapes, and surface finishes. The pushrim most commonly found on wheelchairs is about ½ inch in diameter with a smooth surface finish and round cross-sectional area (see Figure 17-1). Persons who have limited gripping ability (e.g., low-level cervical injuries) might need a larger diameter pushrim or a high-friction surface finish (e.g., vinyl or foam), or both. Sometimes these individuals need a pushrim with vertical, horizontal, or angled projections (Figure 17-11, A) to be able to effectively propel their wheelchairs. New designs provide for greater surface area (Figure 17-11, B) and are also contoured for a more natural hand grip.

Lever Drives

Propelling the wheelchair using levers versus pushrims has proven to be more mechanically efficient. Dual-lever drive wheelchairs are more common in Europe, China, and other countries of the Far East. They are well suited for persons who frequently propel long distances and over outdoor terrain (e.g., dirt roadways). The drawbacks to using a lever drive system include difficulties with maneuvering in tight places, transfers, and transportability. Single-lever drive systems are quite popular in the United States and allow for the wheelchair to be propelled using one arm (Figure 17-12).

Antitippers

Antitippers are devices that attach to the rear of the wheelchair frame and usually have adjustable length tubes with small wheels at the end (see Figure 17-7). These devices protect the user from tipping the wheelchair backward, but can make it difficult for the user to ascend a curb or pop a wheelie. The tube length can be adjusted to allow the user to traverse over small obstacles while still providing some stability. All new manual wheelchairs generally come equipped with antitippers; however, high-end users often remove them after receiving the wheelchair.

Geared and Power-Assisted Wheelchairs

Geared and power-assist devices are appropriate for individuals who use or prefer their manual wheelchairs for mobility, but who need some assistance to reduce the physical effort required to self-propel. These devices are particularly likely to help those with muscle paralysis or weakness, overuse, and fatigue. They are also ideal for individuals who are apprehensive about transitioning to a fully powered wheelchair. This can be due to not wanting to be viewed by peers as being “more disabled,” having homes that do not accommodate the increased size, lacking the financial resources, or having difficulties with transportation. A geared wheelchair does not require batteries and works similar to a bicycle, allowing the user to shift into a lower gear when climbing hills or rolling over uneven or rough terrain. Power-assist devices include stand-alone powered units that are external to the wheelchair and that the wheelchair user holds on to. Another is a power add-on device that attaches to the wheelchair and has a steering mechanism or input device for controlling the wheelchair. Figure 17-13 shows a pushrim-activated system with motors in the wheelchair hubs. Geared and power-assist devices cost less than a fully powered wheelchair system, but require that the individual has a manual wheelchair that is compatible with the power-assist device.

Research has shown that using a geared or pushrim-activated wheelchair results in significant reductions in the physical and physiologic demands of propulsion compared with using a manual wheelchair.11,22 Power-assist devices can increase the width or length of the manual wheelchair base a few inches. Both geared and power-assist devices are more difficult to transport than manual wheelchairs, mainly because the equipment adds between 10 and 50 lb to the wheelchair. This is still considerably lighter, however, than a fully powered wheelchair.

Power Wheelchairs

People who do not have the strength or stamina to propel manual wheelchairs typically need power wheelchairs for mobility independence. Power wheelchairs can be grouped into four broad categories based on wheelchair features and their intended use: (1) conventional power wheelchairs; (2) folding and transport power wheelchairs; (3) combination indoor-outdoor power wheelchairs; and (4) heavy-duty indoor-outdoor power wheelchairs.19

Conventional Power Wheelchairs

Conventional power wheelchairs are not programmable (e.g., no adjustments in acceleration or deceleration, turning speed, joystick sensitivity) and have very basic seating with limited sizes available (Figure 17-14). They are low cost and low quality (see the duscussion of wheelchair standards). They are appropriate for limited indoor use for individuals with good trunk control who do not need specialized seating.

Folding and Transport Power Wheelchairs

Folding and transport power wheelchairs are designed for easy disassembling to facilitate transport (Figure 17-15). They are usually compact for indoor use and have a small footprint (i.e., area connecting the wheels) for greater maneuverability in confined spaces. They might not, however, have the stability or power to negotiate obstacles outdoors. The batteries are often housed in separate boxes having easy-to-separate electrical connectors. These wheelchairs are typically used by individuals with reasonably good trunk and upper body control.

Combination Indoor-Outdoor Power Wheelchairs

Combination indoor-outdoor power wheelchairs (Figure 17-16) are often purchased by people who wish to have mobility indoors (home, school, work) and in the community, but who stay on finished surfaces (e.g., sidewalks, driveways, flooring). These wheelchairs are equipped with standard proportional joysticks and standard programmable electronics (e.g., speed adjustment, tremor dampening, and acceleration control). They come with either standard seating (such as that shown in Figure 17-17) or rehabilitation seating (see Figure 17-16). Rehabilitation seating allows for the attachment of modular seating hardware (e.g., backrests, cushions, laterals, hip guides, and headrests).

Heavy-Duty Indoor-Outdoor Power Wheelchairs

Heavy-duty indoor-outdoor power wheelchairs (Figure 17-18) are for use by people who live in communities without finished surfaces. These wheelchairs usually have large-diameter drive wheels with heavily treaded tires or four-drive wheels for climbing obstacles and traversing rough terrains. Wheelchairs that can support persons who weigh more than 250 lb also fall under this category. These wheelchairs usually weigh 300 to 500 lb.

Power wheelchairs typically use two deep-cycle lead-acid batteries in series, each producing 12 V, for a total of 24 V. There are two types of lead-acid batteries: wet-cell batteries and gel-cell batteries. Gel-cell lead-acid batteries are generally recommended because there is no potential for chemical spills and they are maintenance free.

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree