Chapter 26 The Shoe in Sports

CHAPTER CONTENTS

General Considerations

Construction

Although product development and marketing methods are different, manufacturers use most of the major methods of shoe construction in the production of sport shoes (Fig. 26-1).

The last

The last, a three-dimensional (Fig. 26-2) form on which the shoe is made, is considered by many to be the foundation for shoe production and development. Foot shape may vary with sports activities, and this is a major area of concern in the development of the last. The shape of the shoe toe box, instep, girth, and foot curvature are determined by the last. The biggest last variations occur in girth (or widest part of the forefoot) and in heel width.

Materials

Lasting Techniques

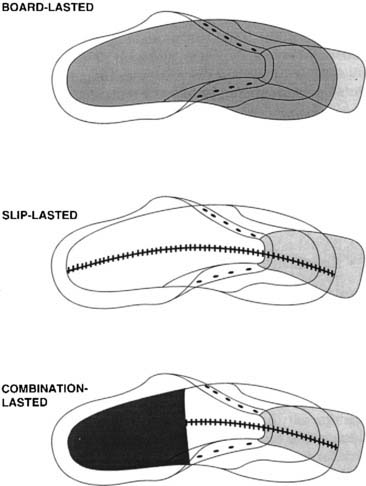

The most common methods of lasting used in shoemaking are slip lasting, board lasting, and combination lasting (Fig. 26-3).

Upper Designs and Cuts

The Outer Sole

Outer sole designs

Patterns can enhance stability and traction. They also can improve shoe lightness by exposing the middle part of the midsole, thereby eliminating part of the outsole and the associated weight. The design of the outsole (Fig. 26-4) can provide cushioning, traction, pivot points, flexpaths, and wear plugs.

Figure 26-4 Outsole patterns.

From Reyatt T: The first step: know your feet. SHAPE Magazine, Nov 1992.

Outsoles are specific for surface, weather condition, and sport. Outsole options include:

Traction provided by the outsole is an important consideration in the design of a sport shoe and is directly related to the ability of the shoe to develop frictional forces with the playing surface. Traction needs depend on the specific sports needs. Too little traction may have a negative effect on athletic performance, and too much traction may put the athlete at risk for injury.1

Cleated shoes must address a compromise between performance and protection of the athlete. Rotational traction, which is expressed by the torque about a normal axis that is developed to resist rotation of a shoe on a playing surface, must be reduced to decrease the incidence of injury while providing sufficient traction. Both cleat length and outsole material affect friction. Torg and Quendenfeld1 concluded that the increased rotational traction characteristics of some football shoes are related to an increase in number of significant knee injuries.

The necessity for lateral movement with court sports makes the traction characteristics of court shoes important. A flat outsole pattern develops the greatest frictional forces, whereas a herringbone pattern develops less.2 With sprinting, initial ground contact is made with the front of the shoe. At foot strike a large horizontal velocity is created, resulting in a high braking force that can cause a backward slide. Anterior spikes help to prevent slipping. With jumping events, an athlete converts the large horizontal momentum of run-up to a vertical momentum at foot plant. The spikes prevent foot slip and allow the development of large propulsive forces necessary for long jump and triple jump.

Boating shoes require a large amount of natural rubber to prevent slippage on wet surfaces.

Midsoles and Wedges

Combination or prefabricated soles

Some midsoles can be contoured to the foot and are referred to as more stable, anatomic midsoles.

The effect of shoe midsole composition on the amount of tibial strain produced with walking has been studied by Milgrom et al.3 Their study was designed to test the hypothesis that shoe sole composition can affect the level of bone strain and strain rates that can lead to a stress fracture. The sole materials tested were various polyurethane midsoles and one of polyurethane with embedded air cells. The sole composed of polyurethane with embedded air cells had significantly lower compression and shear strains and shear strain rates. They concluded that the polyurethane sole with the embedded air cells potentially could protect against stress fractures in a walking shoe.

Other Component Parts

New Components and Designs

Air soles

First introduced in 1979 by Nike, this concept used encapsulated air units in the midsole to enhance cushioning. Ambient air (Etonic) or Freon (Nike) also can be used. Depending on the model, the air units may be in the heel, forefoot, or both. Initial reports noted that, although air systems had superior shock absorption and potential energy rebound, stability was poor.4 Stability in the context of sports refers to the ability of the shoe to resist excessive or unwanted motions of the foot and ankle. Shoes with soft, well-cushioned midsoles allow significantly more motion than firmer shoes, and a poor design can encourage instability. Newer designs have addressed the stability problem with success. Air systems are not as susceptible to compaction as EVA, PU, and other midsole materials and therefore are thought to be more durable.

Energy return

Compression of a viscoelastic midsole material allows a small amount of strain energy to be stored in the compressed elastic components of the midsole. Theoretically, when weight is released the elastic components spring back and stored energy is returned to the athlete. It has been suggested that by increasing the energy return of a shoe, the oxygen cost of an activity can be reduced and performance enhanced. There is little evidence to support these claims. The arch of the human foot is also a viscoelastic system and therefore can return energy.5,6

< div class='tao-gold-member'>

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree