Chapter 20 Protective equipment to the upper limb in sport

Orthoses for the upper extremity in sport are used to protect normal anatomy from increased forces or to protect injured anatomy from normal forces. Protective equipment attempts to (1) decrease motion of certain body parts, (2) support and/or compress an area of prior injury, (3) reduce friction between surfaces, and/or (4) absorb energy of a direct blow, dispersing the force over a larger area.16

To be effective, protective equipment must be properly fitted, well maintained, and made of a durable, lightweight material that is reasonably priced and appropriately designed for the designated task. Proper fitting of equipment is essential, as the most expensive, expertly designed and fabricated equipment, if too big or too small, loses its effectiveness.21 For recreational sport, style is also a concern. For example, wrist guards and helmets for rollerbladers became more acceptable to youngsters when manufacturers started making them in bright colors and had them signed by well-known bladers. The effectiveness of protective equipment was demonstrated in a study comparing the injury rate in American football players to New Zealand rugby players. The injury rate in football players utilizing protective equipment was approximately one third that of rugby players who wore no protective equipment.12

Fabricators of protective equipment frequently use composite materials. Soft, lower-density, absorbent materials can be layered with a dense material for greater force absorption. Protective equipment that covers joints not only should be soft to the skin but also must be flexible enough to not limit joint motion. Protective equipment, designed to protect an area of prior injury, may need to incorporate hinges or check-rein straps to limit motion.

Materials used to make protective orthotics

Wraps and tapes

Cloth-backed tape is available in a variety of widths (0.5–3 inches). When ordering tape, consider tape grade, adhesive mass, and winding tension. The higher-grade tape has greater strength, which results from an increased number of threads per inch in both the vertical and longitudinal dimensions.1

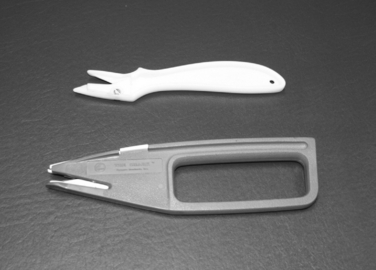

To remove tape, tape cutters (Fig. 20-1) are recommended in lieu of scissors because they have protective tips to avoid cutting the skin and are made to slide easily under the tape’s edge.

Rigid thermoplastic materials

Rigid thermoplastic materials include plastics, elastomer or rubberlike materials, or a combination of these two. Orthoplast, Multiform (Alimed, Dedham, MA), Aquaplast, Polyfoam (Smith & Nephew), Polyflex, and Ezetoy (Smith & Nephew) are common thermoplastic materials used to make rigid splints.19 Plastic is more conforming than rubberlike materials and is used for smaller splints (e.g., those used for the finger). Both materials come in conveniently sized solid or perforated sheets.

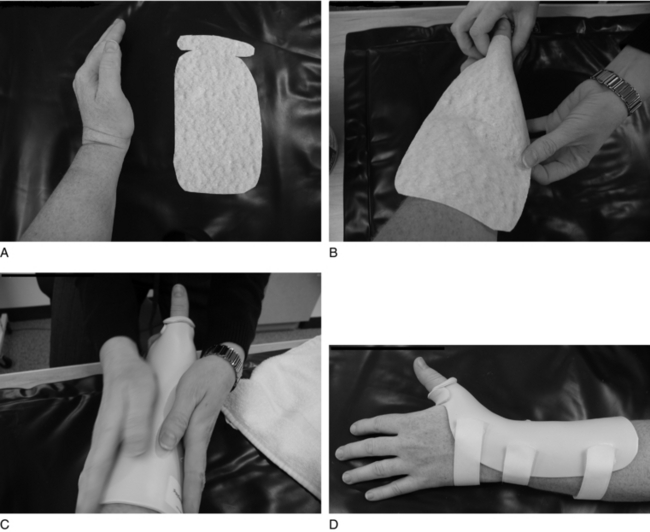

To make a splint from thermoplastic materials, typically a pattern is first fashioned from paper, which can be easily folded when custom fitting it to the area. Using this pattern, the appropriately shaped piece of thermoplastic material can be cut, softened with heat (typically 150°–180°F)* either by immersing it in a hydrocollator or by using a heat gun and molded to the body part. The fabricated brace can be securely attached to the athlete by hook-and-loop straps, elastic webbing, or elastic or cloth tape, or it can be incorporated into the pockets of the uniform (Fig. 20-2). Prefabricated splints from these materials are available. When designing protective pads, one must be certain that the material selected for fabrication is permitted by the sport.

Governing bodies for sport typically determine the materials that are to be used. Regulations may vary depending on the sport, the age of participants, and the level of competition. The National Federation of High Schools (NFHS, Indianapolis, IN) and the National Collegiate Athletic Association (NCAA, Indianapolis, IN) may have additional rules. Splints and pads should protect the athlete but should not be able to be used as a weapon against the opponent, nor should they provide an unfair advantage to the athlete.

Open-cell and closed-cell foam pads and splints

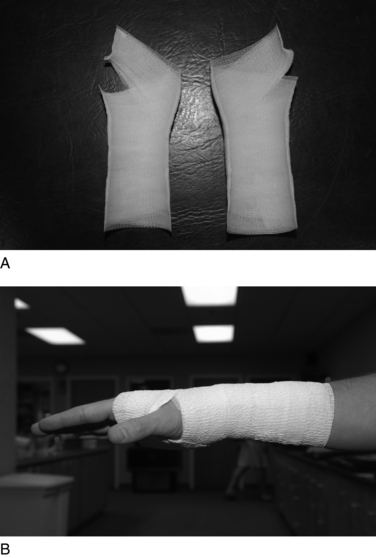

Silicone elastomer (Smith & Nephew or Dow Corning Corp., Midland, MI) is a liquid-type material that reinforces gauze bandages. When activated by a catalyst, it forms a soft splint material that can be used for casts and splints when more rigid materials such as plastic and rubberlike (elastomer) combinations or polyethylene or EVA foams are not permitted by the sport.3,4 Soft casting tape (e.g., 3M Healthcare) also can be used for this purpose (Fig. 20-3). After the splint is fashioned and allowed to harden, the device is bivalved so that, if needed, it can be replaced with a more rigid cast/splint for everyday uses. The softer splint is taped in place for play, practice, and competition.

Examples of protective equipment

Shoulder

Pads for protection

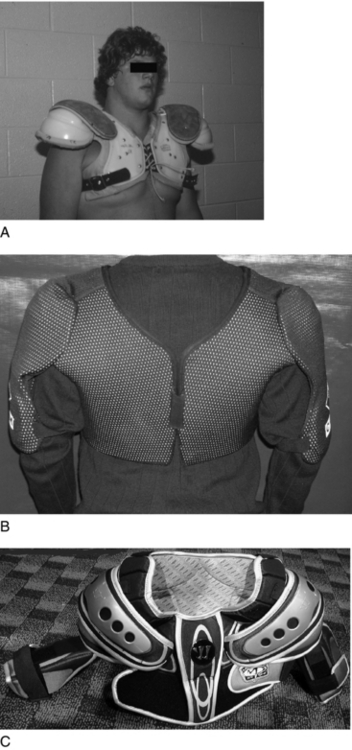

Football pads provide the player with greater protection than do hockey or lacrosse shoulder pads (Fig. 20-4). Attachments such as rib and back plates, biceps pads, and neck rolls add further levels of protection (Fig. 20-5). To decrease the incidence of injury and improve comfort, manufactures have added ventilation systems (e.g., Temperature Management System, Williams Sports Group, Jacksonville, FL). While on the sidelines, players connect small air hoses to their pads and can circulate cooled air through ventilation channels in the interior of the pads.

In football, shoulder pad selection is position specific. Offensive and defensive skill positions generally require smaller pads for greater glenohumeral mobility. However, receivers, running backs, and quarterbacks often require greater coverage of the chest, ribs, and back because these areas may be targeted by the opponent. Increased protection is required for tight ends, fullbacks, and linebackers, but not at the expense of mobility. Linemen exposed to constant contact impact have the least requirements for shoulder mobility and require the greatest amount of protection. Despite the differences in shoulder pads, the same fitting principles apply. Padding should cover the lateral extent of the shoulder; cups and flaps should cover the deltoid; straps should be snug to minimize movement; and the neck opening should not constrain the arms when they are fully abducted (Fig. 20-6). Ancillary padding for the acromioclavicular (AC) joint can be used as standalone devices or used in conjunction with shoulder pads to help protect the area following injury or to help protect the area from injury. The most basic supplemental protection to the AC joint is a doughnut pad placed over the joint, often made from dense foam (Fig. 20-7, A). This device can be worn with shoulder pads or as a standalone pad in sports in which a hard-shell orthosis is prohibited (e.g., wrestling). Shoulder injury pads (Adams USA, Cookeville, TN; Fig. 20-7, B) are commercially available lightweight pads that can be worn to elevate shoulder pads and thus provide additional capacity for force dispersion. However, these pads can interfere with proper fitting of the standard shoulder pads causing migration. Rather than purchase a prefabricated plastic shell shoulder pad, a custom pad can be constructed from moldable thermoplastic material. Care must be taken when making the splint to create a dome over the AC joint so that the pad does not contact the joint itself. The pad is held in place with tape or a strap.

< div class='tao-gold-member'>

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree