Ceramic on Ceramic

Amir-Reza Jenabzadeh

William L. Walter

Case 1

MJ is a 66-year-old lady who had a ceramic-on-ceramic hip replacement 1 year ago. She is doing well in her 1-year follow-up. She is pain free and manages all her activities of daily living. She is very pleased with the hip but mentions that she has noticed an occasional “squeak” from her hip on certain movements. She asks if this is something she should be worried about.

Squeaking

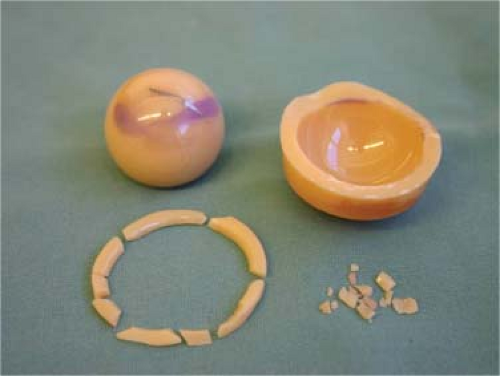

Squeaking is defined as a high-pitched, audible sound that occurs during movement of the hip joint. This is an uncommon finding associated with ceramic-on-ceramic bearings (Fig. 91.1) (1,2). The implications of squeaking are not yet fully understood.

Squeaking was first described in the 1950s with Jude’s acrylic hemiarthroplasty (3). Charnley (4) noted in vitro squeaking when he tested one of Boutin’s ceramic-on-ceramic bearings in his “pendulum friction comparator.”

The incidence of squeaking associated with ceramic-on-ceramic bearing surfaces has been reported as ranging from <1% to 21% depending on how the sound is defined (5,6,7,8). In a review of 2,406 patients from our unit we had an incidence of 3.1% at a mean follow-up of 9.5 years (9).

Etiology

Squeaking of ceramic-on-ceramic bearings is multifactorial requiring a certain combination of interaction among patient, implant, and surgical factors.

Patient Factors

Squeaking hips have been shown to be associated with younger, heavier, and taller patients (12). Patients with squeaking hips have significantly higher activity levels (9). These factors may be associated with increased mechanical demands. Squeaking is associated with certain activities, such as walking, bending, and rising from a low sitting position. This indicates that noise is produced with either cyclical movement during the gait cycle or during extreme flexion of the hip in bending.

Implant Characteristics

Bearing material and implant design are important contributing factors. Squeaking has also been reported following fracture of the ceramic liner (Fig. 91.2) (13,14), and in a patient with mismatched bearings where a zirconium ceramic head was coupled with an alumina ceramic cup (15). As for the alumina ceramic, the femoral head size, cup size, and stem size have not been shown to correlate with squeaking (2,8), although a short neck length may be associated (8). Interestingly, when different studies are compared, the groups that used the Trident acetabular component reported higher incidences of squeaking. Whether the design factors of the implant contribute to the production of the squeaking remains to be investigated.

Recent studies have shown that the design of the femoral component may explain why certain hip systems have a higher incidence of squeaking than others (16,17). In one study the Accolade (Stryker) and the Omnifit (Stryker), both used with the Trident acetabular component, reported a higher incidence of squeaking in the Accolade system, which has a narrower neck and is made of titanium alloy material with lower stiffness. It may be that a more flexible stem is associated with squeaking or that a different titanium alloy may influence the rates of squeaking. Aspects of stem design, such as material used and weight, shape, and geometry, may affect the resonant ability of the stem, which is important to squeaking.

Surgical Technique

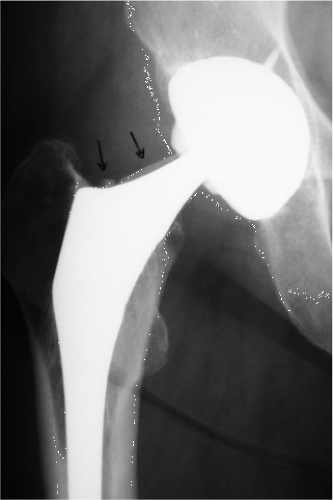

Malpositioning of the acetabular component and impingement (Fig. 91.3) have been associated with squeaking (6). To reduce the risk of squeaking, it is recommended that the acetabular component have an inclination of 45 ± 10 degrees and an anteversion of 25 ± 10 degrees (12). Four implant position factors enable good prediction of squeaking. These are high acetabular component inclination, high femoral offset, lateralization of the hip center, and either high or low acetabular component anteversion (13). Factors

which increase the mechanical forces across the hip joint and factors which increase the risk of neck-to-rim impingement, and therefore edge loading, are those that predispose to squeaking. However, one should note that squeaking can also occur with correctly positioned implants in the absence of neck-to-rim impingement (12).

which increase the mechanical forces across the hip joint and factors which increase the risk of neck-to-rim impingement, and therefore edge loading, are those that predispose to squeaking. However, one should note that squeaking can also occur with correctly positioned implants in the absence of neck-to-rim impingement (12).

Benign Versus Problematic Squeaking

Benign Squeaking

This is the most common form of squeaking encountered. The patient usually experiences no pain, and hip function is not affected. They do notice intermittent squeaking which is usually brought on with a specific activity and well tolerated. The components are well positioned in these cases and there is little or no wear.

Investigation

History and Clinical Examination

A thorough history and examination should be performed to see if patient can reproduce squeaking and what position this is in. Examination should focus on range of movement of the hip with any signs of impingement.

Imaging

All patients require radiographs of the hip to exclude any obvious malpositioning, implant failure, or fracture (Fig. 91.4

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree