5 Percutaneous Pedicle Screw Systems

5.1 Introduction

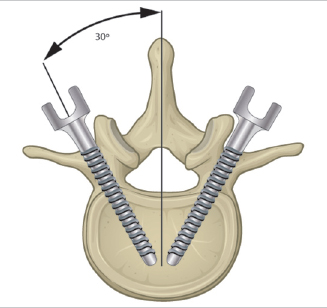

Pedicle screws evolved from the original facet screw technique to improve spinal internal fixation while maintaining vertebral range of motion.1 With the use of plates or rods, pedicle screws can provide load sharing between vertebrae, improving overall fixation and preventing vertebral collapse.2,3 Multiple methods have been developed to improve pedicle screw fixation strength, such as improving insertional torque, cross-linking adjacent screws, and triangulating the insertion of the screw.2 In minimally invasive spine surgery, percutaneous pedicle screw insertion techniques are utilized. The pedicle screw is oriented approximately 30° from vertical to allow for accurate pedicle insertion in addition to improving screw pull-out strength (▶ Fig. 5.1).4 Surgical indications for percutaneous pedicle screws are described in ▶ Table 5.1.

5.1.1 Pedicle Screw Components

A pedicle screw is composed of a head, or tulip, neck, and shaft. The head is where the rods are placed to interconnect consecutive screws. Screw heads can be fixed (monoaxial) or can allow motion at the shaft–head interface (polyaxial). While polyaxial screws allow for easier rod insertion, they are also associated with failure at lower loads and greater rates of screw-head slippage than monoaxial screws.5,6 Monoplanar screws have also been introduced, which allow for motion in the axial plane while maintaining rigidity in the sagittal plane.7,8 In percutaneous pedicle screw placement, tulip extensions provide a corridor through which the screw head can be accessed from outside of the patient.9 These extensions can either be removable or fixed with a break-off tab for removal. Tulip extensions are traditionally rigid, but can be malleable or lie flat against the skin for increased visualization. Additionally, some systems have capabilities for reduction or deformity correction. However, literature comparing the efficacy between tulip extension designs is limited and thus, choice of system is largely based on surgeon preference.

Table 5.1 Surgical indications for percutaneous pedicle screws

Indications |

• Posterior approach spinal fusion • Thoracolumbar procedures • Degenerative disk disease • Spondylolisthesis • Spinal fracture/dislocation • Spinal stenosis • Spinal deformity |

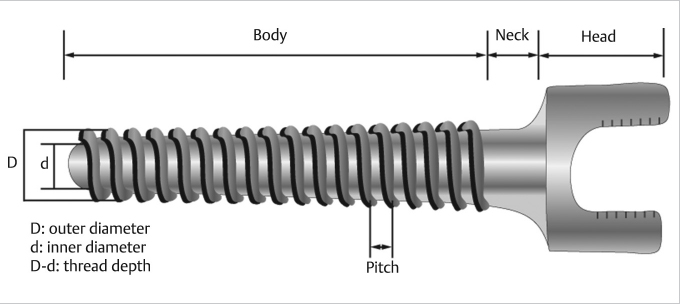

The screw shaft can be conical or cylindrical in shape. Conical screws have previously been associated with greater insertional torque and bending performance.10,11 However, concerns exist regarding the pullout strength of conical screws when backed out 360°.12 The shaft also contains the threads of the screw. The height and size of the thread crests determine the inner and outer diameter of the screw shaft (▶ Fig. 5.2). The outer diameter of the screw shaft has been identified as a major determinant of pullout strength, while the inner diameter is reported to determine the fatigue strength.12,13 Different thread options are available, including double lead and dual thread screws which facilitate faster insertion and increase insertional torque.12,14 The distance between the crest of each thread is called the pitch, and this measurement is also thought to be crucial in determining pullout strength of the screw. When screw pullout occurs, the bone in between the crests of each thread is often fractured. As such, the amount of bone in between the threads and the quality of bone can directly impact screw strength.

Percutaneous pedicle screw placement is performed by using Kirschner wires to determine accurate trajectory under fluoroscopic guidance. Cannulated screws are then introduced over the guidewire. The hollow core of cannulated screws has raised concerns over increased risk for screw breakage as compared to solid screws. Studies have suggested that cannulated screws exhibit decreased mechanical strength, stiffness, and axial failure loads when compared to solid screws of similar diameters.15,16 As such, it is recommended that cannulated cores not exceed 2.0 mm in diameter.17 However, previous reports have determined that cannulated conical screws are able to maintain the bending performance of solid screws, suggesting that conical designs are preferred for cannulated screw placement.18,19 Newer designs have been proposed that use an additional pin to fill the cannulated core in an attempt to recreate the structural stability of the solid screw. However, this design has not been determined to improve the bending performance of cannulated screws.18