, Paul D. Siney1 and Patricia A. Fleming1

(1)

The John Charnley Research Institute Wrightington Hospital, Wigan, Lancashire, UK

From Low Friction to Low Frictional Torque

“In a design of a load bearing joint I have rather lost interest in the coefficient of friction between the materials of the rubbing surfaces as a guiding factor in design. It is possible to circumvent the coefficient of friction by concentrating on low-frictional torque in the assembled unit by reducing the diameter of the ball” … “It was pointed out to me that the best engineering practice would be to use the smallest diameter ball which could cope with the expected load. Resistance to movement of the head in the socket is greatly reduced by reducing the radius of the ball and therefore reducing the “moment” of the frictional force. If, at the same time, the radius of the exterior of the PTFE socket is made as large as possible, the “moment” of the frictional force between the socket and the bone will be increased and this will lessen the tendency for the socket to rotate against bone. The result of reducing the size of the femoral head was to prolong the period during which the success was absolute.”…“Since there was no way of estimating rigours of service in the human hip joint over a period of years, we had to proceed by trial and error … from the starting size of 41.5 mm diameter … this was first reduced to 28.5 mm then 25.25 mm and finally to 22 mm” (actually 22.225 mm or 7/8 in.) (1966) (Fig. 2.1). Charnley worked with the then standard Imperial System. The first recorded LFA using 7/8 in. (22.225 mm) head diameter in the Charnley Hip Register is dated 29.09.1960. “Fluon socket arthroplasty – left hip – using 7 / 8 in. prosthesis long neck.

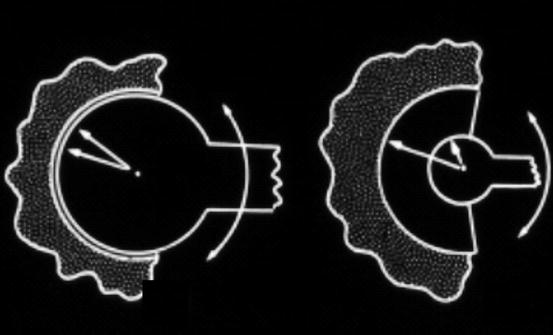

Fig. 2.1

Reducing the diameter of the head of the femoral component from 41.5 down to 22.225 mm

It is this change of concept from “low-friction” the property of the materials to “low-frictional torque” the principle of the design, that marks the fundamental turning point in the evolution of the low-frictional torque arthroplasty; henceforth referred to as the Charnley LFA (Fig. 2.2).

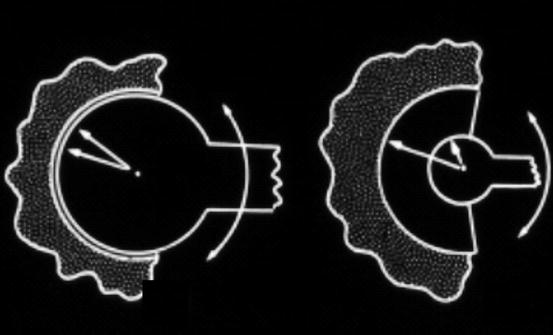

Fig. 2.2

Low frictional torque principle. Difference in the radii of small femoral head with socket of maximum external diameter

Charnley, however, continued using PTFE as the material for the cup. Charnley discussed “low frictional arthroplasty” and its application in rheumatoid arthritis, geriatrics and as a primary procedure in fractures of the neck of the femur. Detailing the operative technique Charnley states “a low-friction socket in Teflon … cemented in position using cold-curing acrylic cement”. (1965) [1].

The “Teflon Era”

Charnley’s experience with Teflon is, unfortunately, better known for the failures than the contributions made to the development of hip replacement. It was during that period that the design of the components, “the mechanical details of the technique became stabilised in the period 1959–1962 in the Teflon era …” (1971) wear characteristics and tissue reaction to PTFE wear particles, histology of bone-cement interface were established. Material suitable for the cup was the one missing link.

Kamangar et al. [2] studied 100 PTFE “pressfit” cups in an attempt to find information supporting the low-frictional torque principle. Majority of the cups, 72, were articulating with the 22.225 mm diameter head, 12 with 25.25 mm, 12 with 28.5 mm and 4 with 41.5 mm diameter heads. Of the 100 cups 58 were not completely worn through; 39 were articulating with 22.225 mm, 11 with 25.25 mm, 6 with 28.5 mm and 2 with 41.5 mm diameter heads. Charnley could not have hoped to find the information he was seeking: Long term successful results would not have been possible, all cups were taken from revisions, they were worn and loose, numbers were small and follow-up short to allow comparison of results with various head sizes. Yet, even when examining failures, Charnley did find very valuable information.

“The most serious aspect of the failure of PTFE was the production of tissue reaction by wear debris”

“wear of the PTFE socket seemed to be more dependent on the activity of the patient than the weight …”

“… the wear of the plastic sockets took place by the steel ball boring into the substance of the plastic to make a cylindrical pathway of the same diameter as the steel head …”

“the rate of volumetric wear found must be directly proportional to the diameter of the sphere…”

“It is concluded that, from consideration of the geometry and the wear characteristics of metal spheres in plastic sockets, the sphere should have a diameter not greater than half that of the external convex diameter of the socket.” (1969); the fundamental basis of the Charnley concept.

The most important, and probably the least known observation, was that the operation was immediately successful – freedom from pain was complete. Patients were prepared to accept further surgery even if the freedom from pain was no more than several years.

The operation had to be abandoned because of rapid wear of the PTFE cups and gross destruction of bone. During this period of despondency cemented Thompson hemi-arthroplasty was used in some cases where the relatively well preserved acetabulum permitted. Such cases were relatively few.

It must be appreciated that by the time PTFE was abandoned the concept of the low-frictional torque arthroplasty was fully established. Not only that – the design and methods of manufacture of the components, including the lapping and polishing of the 22.225 mm diameter head in EN58J stainless steel, but also a full range of instruments and the details of surgical technique were in place. Documentation of clinical assessment, operative details and the study of results of this type of surgery and the Hip Register were also fully established. The one missing link was suitable material for the cup.

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree