CHAPTER 5 Sutures and glenoid anchors for instability

The surgeon should be familiar with the types and composition of suture materials and suture anchors being used in today’s marketplace.

The surgeon should be familiar with the types and composition of suture materials and suture anchors being used in today’s marketplace. Bioabsorbable and biocomposite suture anchors have shown similar strengths, improved postoperative visualization on imaging, and allowed for easier revision surgery than metallic suture anchors.

Bioabsorbable and biocomposite suture anchors have shown similar strengths, improved postoperative visualization on imaging, and allowed for easier revision surgery than metallic suture anchors. A surgeon should master at least one sliding and nonsliding knot. A sliding knot backed up by at least three, preferably four, reversed half hitch knots with switching posts should ensure adequate knot security.

A surgeon should master at least one sliding and nonsliding knot. A sliding knot backed up by at least three, preferably four, reversed half hitch knots with switching posts should ensure adequate knot security. Suture anchors have many potential failure sites; however, the suture-anchor interface, and bone-anchor interface are most frequently sites of failure for glenohumeral stability procedures.

Suture anchors have many potential failure sites; however, the suture-anchor interface, and bone-anchor interface are most frequently sites of failure for glenohumeral stability procedures.Introduction

Product innovation is not the only reason arthroscopic techniques have become the new “gold standard” for shoulder instability surgery; technique changes also play a major role. Thumbtacklike devices that reattach the torn capsuloligamentous structures medially on the glenoid neck have been abandoned because of the recognition that they are creating an anterior labral periosteal sleeve avulsion (ALPSA) lesion instead of reestablishing normal anatomic relationships. The recognition of the need for at least three anterior fixation points, locating the anchor sites on top of the glenoid cartilage (rather than medially on the neck), considering rotator interval closure to address inferior subluxation, adding posterior inferior sutures when appropriate, including a capsular plication stitch to address a patulous capsule, and better knot-tying techniques have all resulted in clinical outcomes consistent with those of open techniques.

Although not an absolute requirement but certainly preferable, biodegradable material is very attractive in a suture anchor, especially for one destined to be placed in the glenoid. While metal anchors were commonly used in the past, biodegradable anchors have comparable pull out strength; do not create problems in revision surgery or postoperative imaging;1 and, with the introduction of biocomposite materials, offer the prospect of osteoconductive behavior leading to their replacement with bone.

Suture material

Dyneema fiber is an ultra-high-strength polyethylene fiber that offers a maximum strength combined with a minimum weight. It is up to 15 times stronger than quality steel and up to 40% stronger than aramid (aromatic polyamide) fibers on a weight-for-weight basis. This fiber was made available to many companies with various braid designs and was introduced into the field of arthroscopic surgery under several different brand names. These brand names include Hi-Fi (ConMed Linvatec, Largo, FL), Force Fiber (Stryker Endoscopy, San Jose, CA), Ultrabraid (Smith & Nephew, Andover, MA), Magnum Wire, (Axya Medical, Beverly, MA, and ArthroCare, Sunnyvale, CA) and MaxBraid PE (Arthrotek, Warsaw, IN) (Table 5-1). The newer UHMWPE-containing sutures have been shown to have 2 to 2.5 times the ultimate strength of traditional braided polyester suture and a 500-fold increase in resistance to fraying.2

Table 5-1 Common Ultra-High Molecular Weight Polyethylene–Containing Sutures

| Suture | Composition |

|---|---|

| FiberWire (Arthrex: Naples, FL) | Braided polyester outer covering, UHMWPE fiber core |

| Orthocord (DePuy Mitek, Raynham, MA) | UHMWPE and PDS (polydioxanone) |

| Hi-Fi (ConMed Linvatec, Largo, FL) | Braided UHMWPE |

| Ultrabraid (Smith & Nephew, Andover, MA) | Braided UHMWPE |

| Force Fiber (Stryker Endoscopy, San Jose, CA) | Braided UHMWPE |

| MaxBraid PE (BioMet Sports Medicine, Warsaw, IN) | Braided UHMWPE |

| MagnumWire (ArthroCare, Sunnyvale, CA) | Braided UHMWPE |

Subsequent to the release of the Dyneema family of braided sutures, Ethicon released Orthocord suture, which is used in many of the DePuy Mitek suture anchors. Orthocord is unique in that it combines UHMWPE with a degradable material. The size No. 2 consists of a combination of UHMWPE (32%) and polydioxanone (PDS) (68%) and is coated with polyglactin 910. The Orthocord design comprises a PDS core with a UHMWPE sleeve.3 This configuration is designed to leave a lower profile suture after the PDS has dissolved while retaining strength from the outer sleeve. It should be noted that the percentage of PDS and UHMWPE differs slightly with the different sizes of Orthocord suture.4

Suture performance and knots

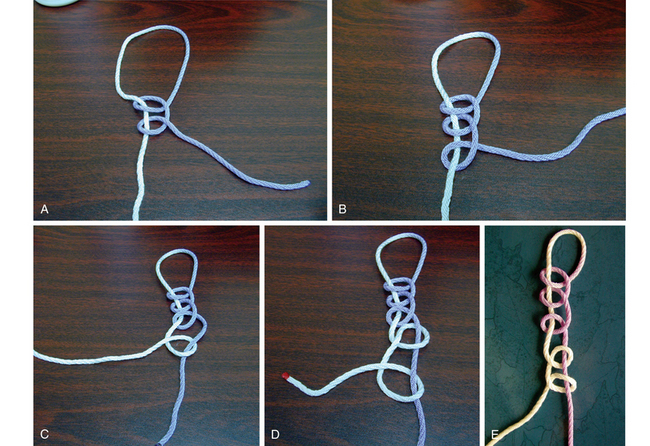

For arthroscopic shoulder instability surgery (as with any arthroscopic knot tying), the surgeon should master two types of knots: nonsliding and sliding knots. Nonsliding knots are used in cases when the suture is caught, frayed, or otherwise cannot slide freely. These consist of a series of half hitches that vary the direction of the throw and alternate the post around which the half hitch is thrown. The most common nonsliding knot (Fig. 5-1), the Revo knot, has been shown to test well compared with sliding knots.5,6 The first two half hitches of the Revo knot are throwing in the same direction on the same post. The third half hitch reverses that direction but uses the same post. These three half hitches are tensioned at this point using a “past pointing” technique with a single lumen knot pusher. Two additional half hitches are then thrown using the other suture limb as the post and alternating the direction of the throw.

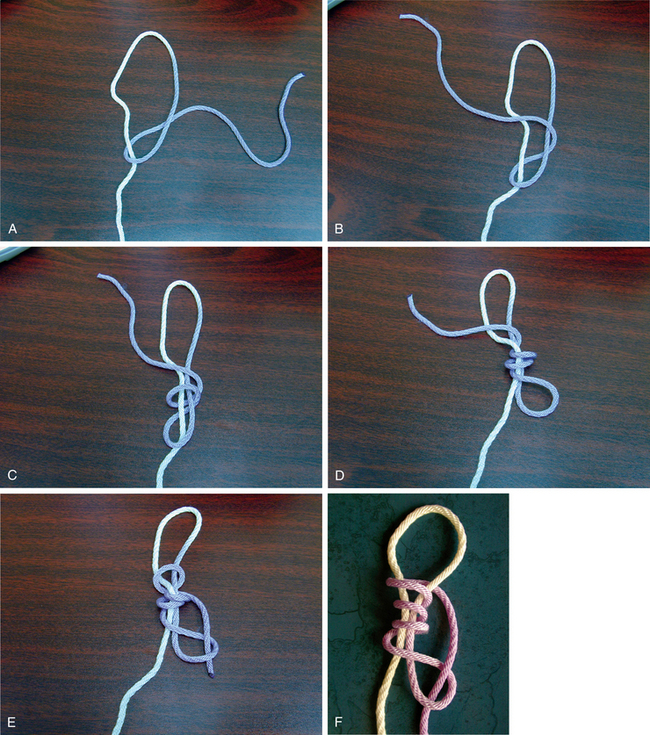

Sliding knots can be subdivided into locking and nonlocking knots. The Duncan knot is a sliding nonlocking knot. To tie a Duncan loop (Fig. 5-2), the sutures are grasped between the thumb and index finger and a loop is created by passing the loop strand over the post. The loop strand continues in the same direction to place four subsequent throws around the post limb. The free end of the loop limb is the passed through the original loop created, and the knot is tightened to remove the slack from the knot configuration. Once the knot is “policed,” the post strand is pulled and the knot advanced. At least three reversed half hitches should be used to reinforce the knot.

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree