Equipment Needed

Robert L. Kalb

Different types of equipment are needed to treat fractures in the office. This chapter presents the equipment that is necessary for fracture management.

CAST EQUIPMENT

Cast Saw

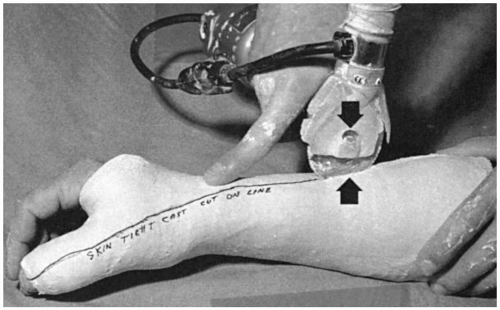

You should become very familiar with operating a cast saw (Fig. 1) so that you do not burn or cut a patient’s skin. The cast saw blade does not turn 360 degrees, as one would expect. Rather, it rotates back and forth in an arc of 30 degrees, which helps prevent cutting the skin.

The technique for operating a cast saw involves holding your hand against the saw with a finger from the hand bridging to the cast, so that if the patient moves the cast, the saw moves along with the cast. This technique is similar to that of using the otoscope on a child: One holds the otoscope with fingers making contact with the child’s head, so that if the child moves his or her head, the otoscope moves as a unit rather than plunging into the ear canal. The proper technique for using a cast saw involves pushing the saw slowly downward through the cast material and then raising the saw completely from the cast and moving in a line toward the end of the cast. At each step of the way, the cast saw takes small 1-in. bites, vertically cutting the cast much as one would perforate paper. This is different from moving the cast saw in a line at the same depth, which can result in cutting the skin. If the cast saw blade becomes hot, turn off the cast saw and let it cool before continuing. This prevents the skin from burning.

There are a variety of saw models and costs. You should choose a cast saw that is affordable. The more expensive models have the advantage of being more quiet and less frightening for patients. If plaster is frequently used, it is wise to have a vacuum canister hooked to the cast saw to prevent dust in the room.

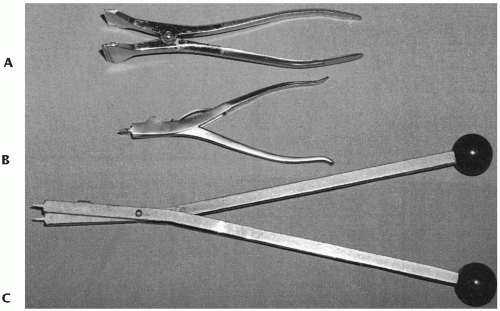

Cast Spreader

Cast Bender

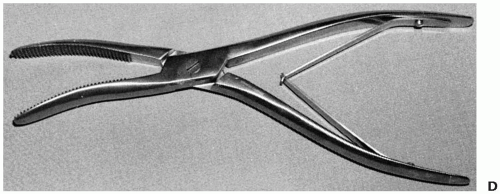

The cast bender (Fig. 2D) is valuable for softening or turning out the margins of the cast where the cast can cut into skin or become sharp at the edges that contact skin. The cast bender is very similar to household pliers. You can grab the end of the cast and bend it outward, like pliers are used to shape the edge of a metal container.

LINER MATERIAL

Webril

The cast padding is made of cotton or synthetic material. The cotton Webril (Fig. 3) is easier to apply than the synthetic material. The synthetic Webril is

more expensive and is more difficult to tear during the application. The only advantage of synthetic Webril is that it tends to hold less moisture and therefore has an advantage in warm, humid climates in conjunction with the use of fiberglass cast materials. Cotton Webril can be used with fiberglass or plaster casting materials.

more expensive and is more difficult to tear during the application. The only advantage of synthetic Webril is that it tends to hold less moisture and therefore has an advantage in warm, humid climates in conjunction with the use of fiberglass cast materials. Cotton Webril can be used with fiberglass or plaster casting materials.

Figure 2 Continued.

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree

Get Clinical Tree app for offline access

Get Clinical Tree app for offline access

|